Low Thermal Expansion Glass Ceramics Pdf

Glass ceramics are normally pro duced in two steps.

Low thermal expansion glass ceramics pdf. The compositions form solid solutions where the elements indicated as. First a glass is formed by a glass manufacturing process. Thermal expansion is the tendency of matter to change its shape area volume and density in response to a change in temperature usually not including phase transitions. This material is produced under tightly controlled conditions and offers outstanding thermal mechanical and chemical properties.

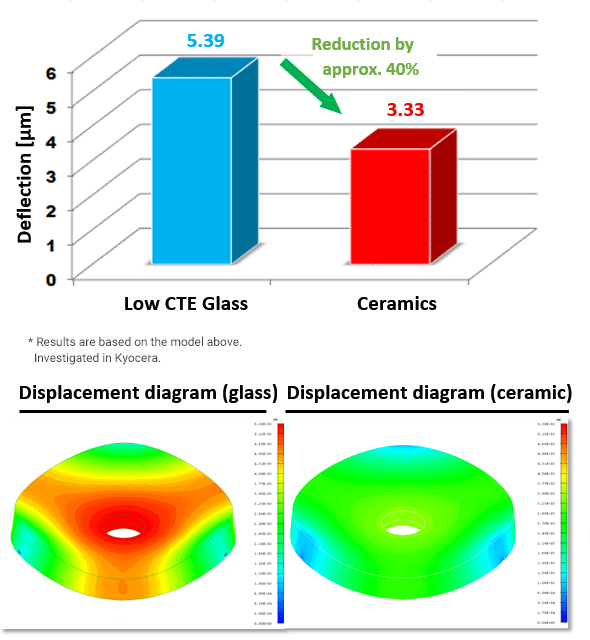

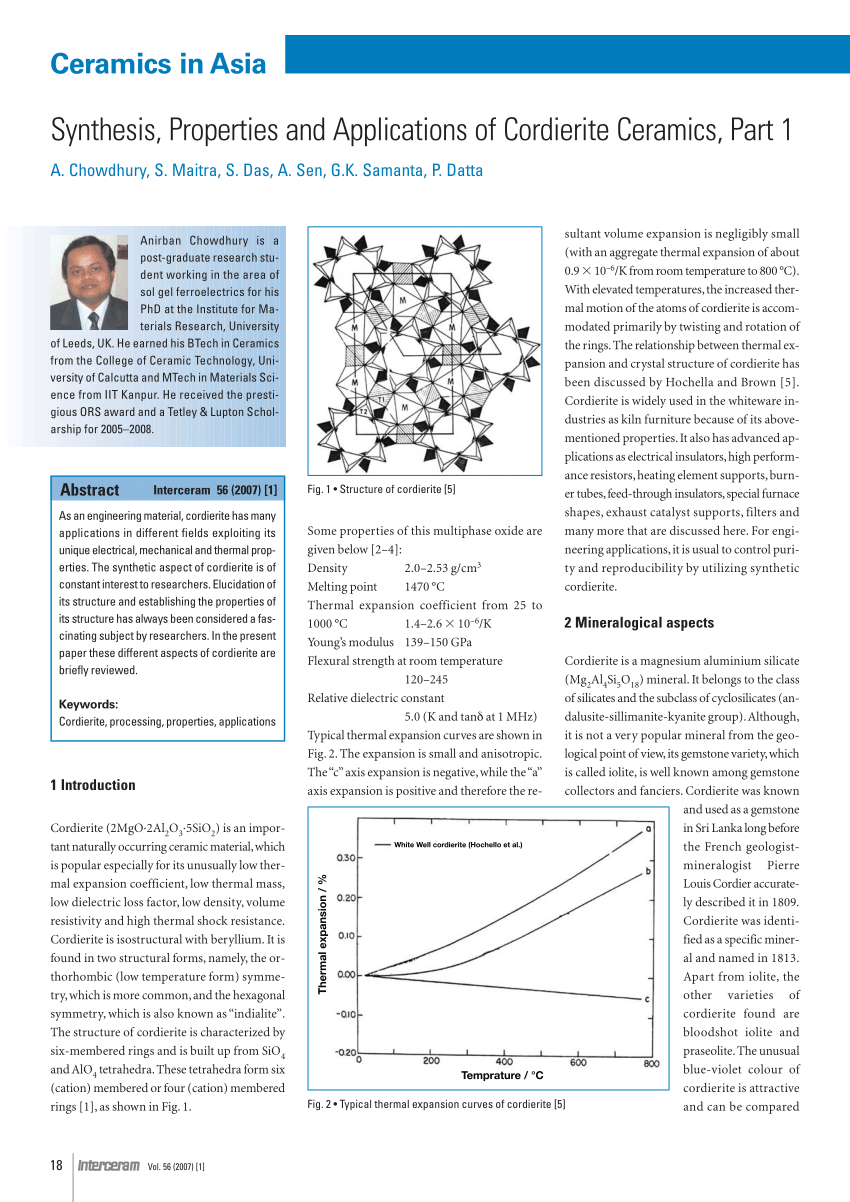

Ultra low expansion glass has an coefficient of thermal expansion of about 10 8 k at 5 35 c. Crystalline phases of the formula am2si2 ygeyo7 a sr and ba and m zn mg ni co fe cu mn with sr ba and zn necessarily having to be present can be produced by conventional ceramic processes or by crystallization from glasses. Low thermal expansion sintered lzsa glass ceramics article pdf available in american ceramic society bulletin 87 7 34 38 july 2008 with 365 reads how we measure reads. Glass ceramics have relatively high mechanical strength low coefficients of thermal expansion.

Glass as well as special properties of ceramics. Glass ceramics are mostly produced in two steps. Temperature is a monotonic function of the average molecular kinetic energy of a substance. Ovenware tableware oven windows clay products one of the most widely used ceramic raw material.

The main aim of the schott series volume low thermal expansion glass ceramics is to describe research and development necessary to produce glass ceramics having low thermal expansion coefficients and to present some prod ucts manufactured at schott which are the results of a successful develop ment. Ceramics and glass ceramics have low and or negative coefficients of thermal expansion. The book is conceived as a monograph. Tage is combining very low thermal expansion coefficient with transparency in the visible wavelength range for cooking ware.

This material is produced under tightly controlled conditions and offers. It has a thermal conductivity of 1 31 w m c thermal diffusion of 0 0079 cm 2 s a mean specific heat of 767 j kg c a strain point of 890 c 1634 f and an estimated softening point of 1490 c 2714 f an annealing. When a substance is heated molecules begin to vibrate and move more usually creating more distance between themselves. This process is called crystallization and the fine grained polycrystalline material obtained is called glass ceramic.

Another is combining very high strength and toughness with translucency biocompatibility chemi cal durability and relatively low hard ness for dental applications.

.jpg)

.jpg)